The Land Transportation Office (LTO) of the Philippines has increased its efforts to modernize and streamline its logistical operations. This is a focus on the production and delivery of vehicle registration plates. Although the agency claims to have resolved the long-standing plate delivery backlog as of late 2025, it continues to experience difficulties related to delivery tracking and transportation inefficiencies.

According to Assistant Secretary Markus V. Lacanilao, recent inspections and audits aim to ensure that license plates reach motorists faster while reinforcing transparency and accountability in the process.

What Is the Current Status of License Plate Production and Delivery?

The LTO, in partnership with its Plate Making Plant (PMP), continues to optimize the production and distribution pipeline. During an official inspection led by Asec. Lacanilao alongside PMP Chief Engr. Oliver Marique, the agency reviewed critical aspects such as supply inventory, production workflow, and logistics coordination. This initiative forms part of a broader move to apply data-driven management and performance monitoring to LTO’s manufacturing and courier systems.

What Led to the Investigation and Audit?

In early reports referenced by TV5 News and ABS-CBN, the LTO confirmed that delays in plate issuance weren’t caused by production shortages but rather by delivery inefficiencies. Many motorists have reported extended waiting times even after registration documents were completed, prompting the LTO to launch a full audit of its courier partners and delivery management system.

Asec. Lacanilao emphasized that the objective is not just speed, but also traceability and accountability, ensuring that every license plate will come from production line to end user.

“We remain focused on transparency and continuous improvement,” Lacanilao noted. “The priority now is strengthening our logistics chain so that delivery bottlenecks are eliminated.”

How Is the LTO Improving Its Logistics and Courier Management?

Both external parties review and internal system modernization are part of the LTO’s current logistical enhancements.

Key Focus Areas:

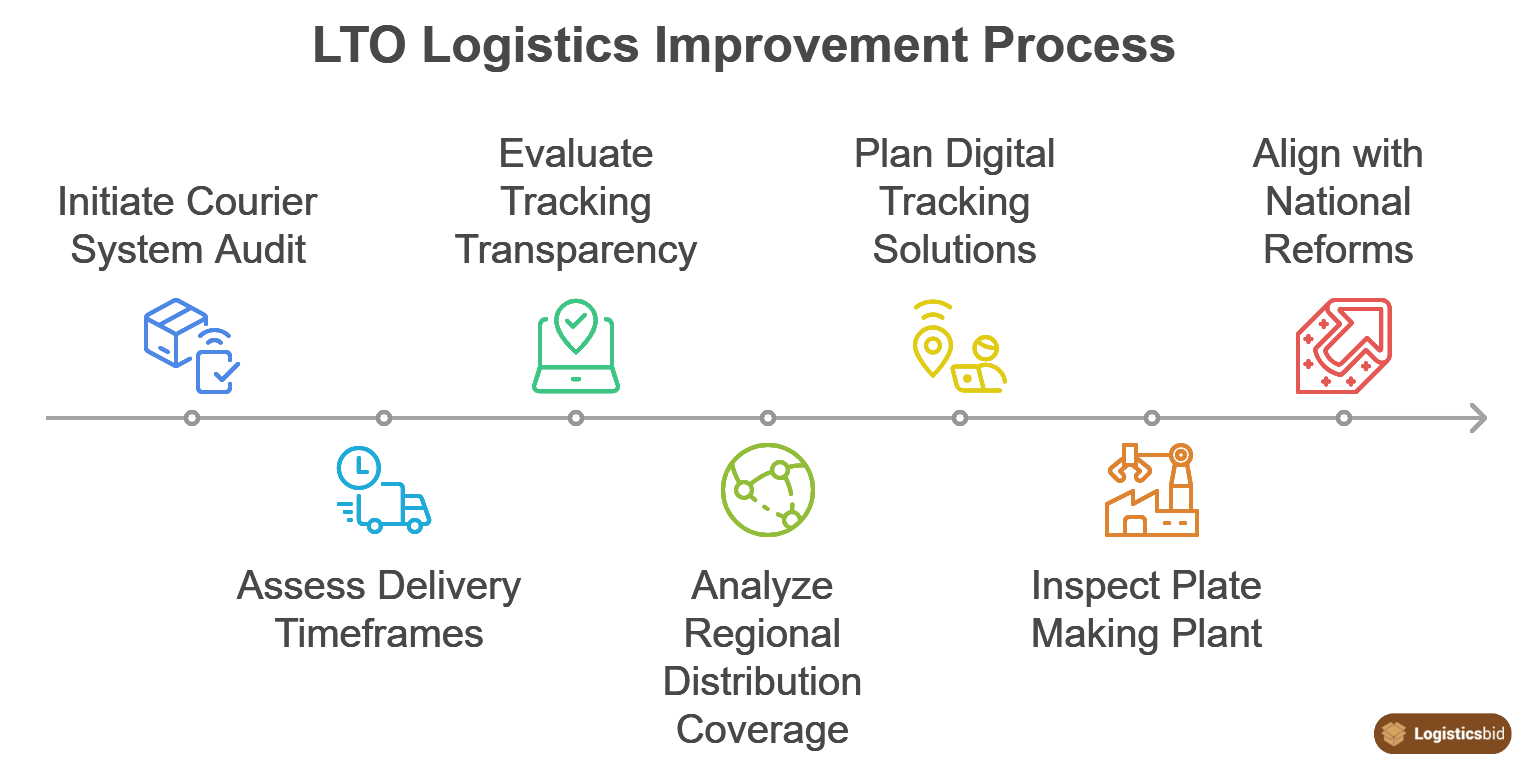

- Courier System Audit – The LTO has initiated an internal review to evaluate plate delivery performance metrics among courier partners. This includes assessing delivery timeframes, tracking transparency, and regional distribution coverage.

- Digital Tracking Solutions – Plans are underway to adopt a real-time tracking system similar to private-sector logistics models used by LBC Express, J&T Express, and Transportify Philippines.

- Plate Making Plant Efficiency – The inspection of the PMP ensures continued compliance with production goals, capacity targets, and supply management.

These actions are in line with the Department of Transportation’s (DOTr) larger national logistical reforms, which place an emphasis on automation, digitization, and data-driven decision-making in all areas of government service delivery.

How Does This Affect Drivers and Vehicle Owners?

For drivers, these reforms are expected to significantly reduce waiting times for newly registered vehicles. While logistical systems are being improved, the LTO has shown flexibility by suspending fines and restrictions for makeshift plates.

Immediate Benefits:

- Plates will be released more quickly after courier efficiency increases.

- During transition, extended validity for makeshift or temporary plates

- Improved communication through public alerts and official LTO social media updates

Owners are also encouraged to verify their vehicle registration and plate status through the official LTO online portal or mobile app, minimizing reliance on manual transactions at regional offices.

Broader Implications for Philippine Logistics

The need for service accountability and process transparency in Philippine logistics is reflected in the LTO’s internal audit. Industries such as government services, retail, and e-commerce are gradually adopting ISO-aligned logistics practices to ensure reliability.

These efforts not only benefit motorists but also strengthen the credibility of public institutions managing critical service plate delivery. Moreover, by working closely with logistics stakeholders, the LTO sets an example for other agencies to follow in improving last-mile delivery performance.

| Focus Area | Initiative | Expected Outcome |

|---|---|---|

| Plate Production | Inspection of Plate Making Plant by Asec. Lacanilao and Engr. Marique | Improved workflow and production oversight |

| Courier System Audit | Evaluation of delivery efficiency and accountability | Reduced delivery delays and errors |

| Policy Response | Temporary suspension of penalties for improvised plates | Public convenience during transition |

| Digital Integration | Adoption of real-time delivery tracking | Enhanced transparency and user trust |

Impact of Plate Delivery on Logistics Operations

While the Land Transportation Office (LTO) has largely resolved the nationwide backlog, the ripple effects of delayed plate delivery can still permeate every layer of the logistics ecosystem. Below we break down the key ways that plate‑delivery lags influence supply‑chain performance, cost structures, and regulatory compliance, and we illustrate each point with real‑world case studies and quantitative data.

Vehicle Downtime and Fleet Availability

| Scenario | Downtime per Vehicle | Cost Impact (₱) | Cumulative Impact |

|---|---|---|---|

| New 20‑tonne truck | 2–3 days without plates | ₱12 000 per day (idle operating cost) | ₱36 000 per truck per incident |

| Freight‑liner | 5 days | ₱25 000 per day (fuel, driver wages) | ₱125 000 per incident |

| Delivery van | 1–2 days | ₱5 000 per day (lost delivery windows) | ₱10 000–20 000 per incident |

Mitigation Tip: Maintain a “plate‑ready” buffer of at least 5 days for all high‑value or time‑critical vehicles.

Compliance Penalties and Legal Risks

| Penalty | Frequency | Total Cost (₱) |

|---|---|---|

| Operating without plates | 1 day per vehicle | ₱5 000 per day |

| Expired plates on commercial vehicles | 7 days | ₱35 000 per vehicle |

| Repeated violations | 3 times | ₱15 000 per vehicle |

Impact on Logistics Providers: A single violation can derail a shipment’s delivery window, forcing the carrier to pay late‑delivery penalties to clients. In high‑volume operations, cumulative fines can reach ₱10 million annually.

Compliance Checklist:

- Verify plate status 24 h before departure.

- Keep digital copies of temporary registration permits for audit trails.

Strategic Recommendations for Logistics Stakeholders

-

Early Plate Procurement

– Submit plate orders at least 14 days in advance.

– Use LTO’s “Pre‑order” feature where available.

-

Leverage Temporary Permits

– Apply for temporary registration for vehicles needed for less than 30 days.

– Ensure compliance with LTO guidelines to avoid penalties.

-

Implement a Plate‑Delivery KPI Dashboard

– Track plate status, delivery lag, and regional performance.

– Set automated alerts for delays beyond 10 days.

-

Diversify Registration Points

– Register vehicles across multiple regional offices.

– Maintain a “backup” plate order in a secondary office.

-

Collaborate with LTO

– Participate in LTO‑hosted logistics workshops.

– Provide feedback on how plate delays affect your operations.

-

Risk‑Based Asset Allocation

– Prioritize vehicles with confirmed plates for critical routes.

– Keep a reserve fleet of vehicles with up‑to‑date plates.

Moving Forward: Building a Transparent and Efficient LTO Logistics Chain

The LTO’s logistics overhaul marks a proactive step toward ending years of inefficiencies in vehicle registration and plate distribution. With ongoing courier audits, infrastructure upgrades, and process transparency efforts, the agency seeks to restore public confidence and ensure that every Filipino motorist receives their license plates on time.

As the LTO moves into full digital integration and logistics modernization, coordination with the DOTr, Department of Information and Communications Technology (DICT), and private logistics providers will be key to sustaining progress.

The LTO’s audit and subsequent resolution of the plate backlog have alleviated many of the systemic bottlenecks that once plagued Philippine vehicle registration. However, for logistics operators, the lingering regional disparities, incomplete digital tracking, and the inherent risk of vehicle downtime remain significant concerns. By adopting a proactive, data‑driven approach, early plate procurement, real‑time monitoring, and close collaboration with the LTO, logistics firms can mitigate these risks, preserve service levels, and maintain compliance across the supply chain.

For updates on logistics efficiency, supply chain trends, and government transport initiatives in the Philippines, visit https://logisticsbid.com/ph/.