The Philippine cold chain industry, for keeping food, medicine, and other perishable goods safe, is entering a new era of innovation through a landmark partnership with the Taiwan Cold Chain Association (TCCA). With demand for cold chain storage and logistics projected to grow by 15–20% annually in the Philippines, this collaboration introduces advanced training, cutting-edge technologies, and improved standards to meet rising consumer and industry needs.

This study tackles a significant issue: the Philippines has long suffered from gaps in the efficiency of the pharmaceutical supply chain and post-harvest losses in agriculture, which the Food and Agriculture Organization estimates can reach 20–40%. By integrating Taiwan tech expertise, the country aims to reduce waste, improve competitiveness, and build a sustainable PH logistics network.

What is the Cold Chain and Why Does It Matter?

Definition and Importance

A cold chain refers to the temperature-controlled supply chain for transporting and storing perishable goods like fresh produce, seafood, dairy, meat, and vaccines. To ensure the best possible product quality, it depends on specialized infrastructure like refrigerated trucks, smart monitoring systems, cold storage facilities, and IoT-enabled logistics software.

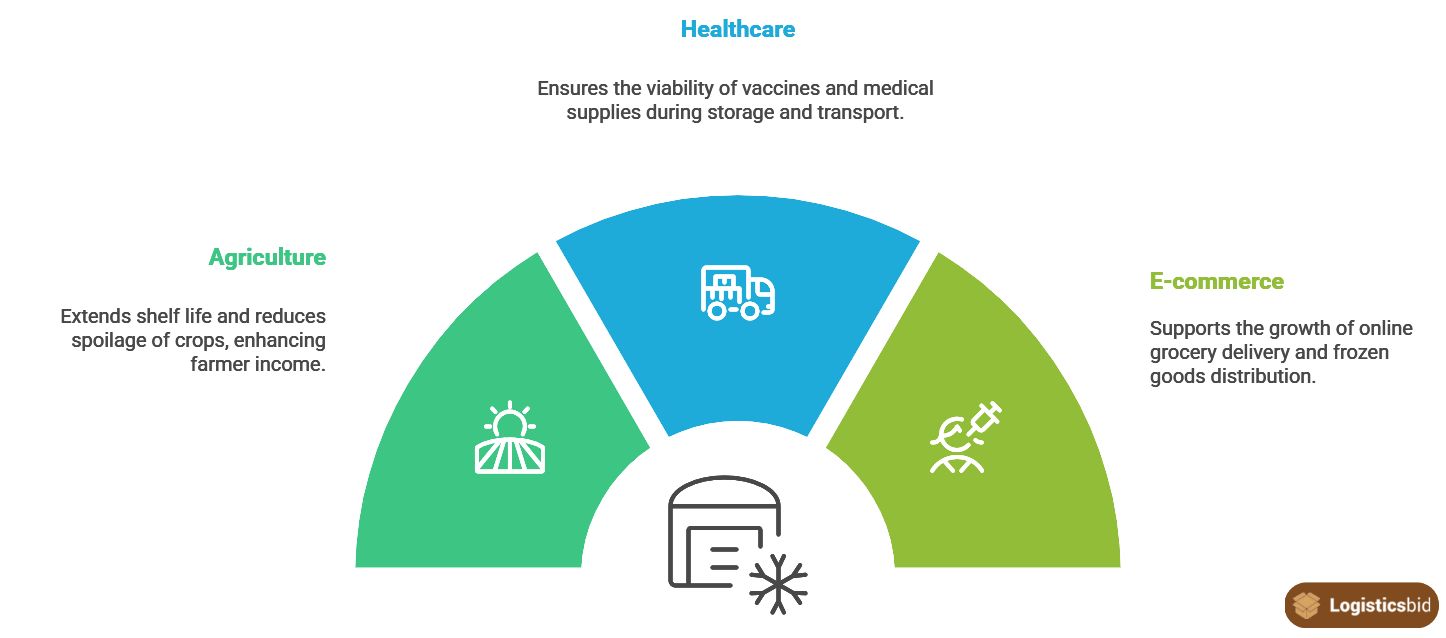

For the Philippines, a geographically diverse archipelago, cold chain logistics is crucial for:

- Agriculture – Extending the shelf life of crops, reducing food spoilage, and improving farmer income.

- Healthcare – Ensuring vaccines, blood, and medical supplies remain viable during storage and transport.

- E-commerce and logistics – Supporting the rapid growth of online grocery delivery and frozen goods distribution.

The strategic economic worth of the Philippine cold chain sector is highlighted by the Department of Trade and Industry’s (DTI) forecast that it will reach USD 4 billion by 2030.

How is Taiwan Tech Helping the PH Logistics Upgrade Its Cold Chain?

Cold Chain Training of Trainers (ToT) Program

At the 23rd Cold Chain Association of the Philippines (CCAP) General Membership Meeting in Boracay, the Philippine National Cold Chain Committee and TCCA advanced the Training of Trainers (ToT) Program. Developed under the Board of Investments’ (BOI) Academe-Industry Matching (AIM!) Program, it aims to:

- Upskill industry professionals and students by embedding advanced cold chain expertise into university curricula.

- Introduce Industry 4.0 technologies such as artificial intelligence (AI), automation, and smart refrigeration.

- Enhance human capital development for long-term sectoral sustainability.

Industry-Academe Integration

The ToT program will be piloted at institutions like University of Makati and Jose Rizal University, with lectures, demonstrations, and immersion programs designed by Taiwan tech experts. Hybrid formats will ensure participation from both on-site and remote learners.

Technology Transfer

According to TCCA CEO Andrew Lin, Taiwan has long invested in training modules that integrate high-tech refrigeration, IoT-enabled monitoring, energy-efficient systems, and best-practice PH logistics. These modules will now be adapted for the Philippine market to:

- Improve food safety compliance

- Optimize storage and transportation efficiencies

- Reduce greenhouse gas emissions through energy-efficient solutions

What are the Benefits of a Stronger Cold Chain for the Philippines?

1. Agriculture & Food Security

- Farmers can reduce losses from spoilage by up to 30% .

- Access to broader markets for perishable goods (fruits, seafood, vegetables).

- Enhanced competitiveness in regional trade under ASEAN Economic Community frameworks.

2. Healthcare and Life Sciences

- Better storage for temperature-sensitive vaccines and biologics.

- Strengthened pandemic preparedness and public health resilience.

- Alignment with World Health Organization (WHO) guidelines on medical cold chains.

3. PH Logistics and E-commerce

The quickly expanding meal delivery and cloud kitchen industries benefit from dependable cold storage.

Logistics companies like 2GO, LBC, and DHL can adopt smarter cold solutions, ensuring faster nationwide coverage.

Comparative Table: Taiwan vs. Philippines Cold Chain Capabilities

| Aspect | Taiwan (TCCA) Strengths | Philippine Current Challenges | Partnership Impact |

|---|---|---|---|

| Workforce Skills | Advanced training programs and certifications | Limited specialized training | Training of Trainers program fills gap |

| Technology Adoption | Smart refrigeration, IoT, energy-efficient design | Traditional refrigeration systems | Technology transfer modernizes systems |

| Industry Integration | Strong government–industry–academe linkages | Fragmented and region-specific initiatives | AIM! Program strengthens ties |

| Global Competitiveness | Export-ready standards and compliance tools | Struggles with post-harvest losses and inefficiencies | Higher competitiveness in ASEAN |

Key Takeaways and Next Steps

- The Challenge: The Philippines faces high post-harvest losses and limited cold chain infrastructure.

- The Solution: Partnership with Taiwan introduces advanced training, Industry 4.0 adoption, and academic integration.

- The Impact: Improved agricultural productivity, stronger healthcare resilience, and enhanced logistics competitiveness.

BOI AIM! With the cold chain industry in the vanguard, the program, which was introduced in 2024, aims to establish the Philippines as a regional center for innovation-driven sectors. The Taiwan-Philippines collaboration thus represents not just technology transfer, but also a shared vision of sustainable and inclusive growth.

The cold chain is no longer just about refrigeration, it is about embedding intelligence, sustainability, and innovation into how nations feed their people and protect public health. With Taiwan tech and Filipino market potential working together, the Philippines is on track to build a future-ready cold chain ecosystem that strengthens agriculture, healthcare, and PH logistics across the archipelago.